BCI Burke Spring Rockers

Industrial Design

BCI Burke was in desperate need of a new line of spring rockers.

To call the old designs “ugly babies” was generous. The original spring rockers were outdated, expensive, and required a lot of time to make. This set the constraints for the new rockers to be aesthetically fresh, inexpensive and quick to manufacture, and more resourceful when it came to materials.

OMPETITIVE ANALYSIS

CONCEPT GENERATION

MATERIAL RESEARCH

CROSS-FUNCTIONAL COLLABORATION

PROTOTYPING

DESIGN FOR MANUFACTURING

ASTM DESIGN

PRESENTATIONBurke’s existing line of spring rockers had been around for quite a long time. While these designs certainly had a sense of nostalgia and charm for parents, they didn’t resonate with a younger generation. Additionally, they were quite expensive and time intensive to make.

We started by taking a hard look at some seriously ugly babies…

We were surprised to find the bar was quite low for spring rocker design

A quick analysis of our competitors’ spring rocker lines revealed that no one had found the sweet spot between cute and sensible. The other designs ranged in overly realistic to absurdly abstract. It seems the designers had chosen to sacrifice form for function. I was interested in finding a harmony between both.

Inspiration was pulled from a variety of mediums.

As we refined the sketches, the designs and material choices started to take shape.

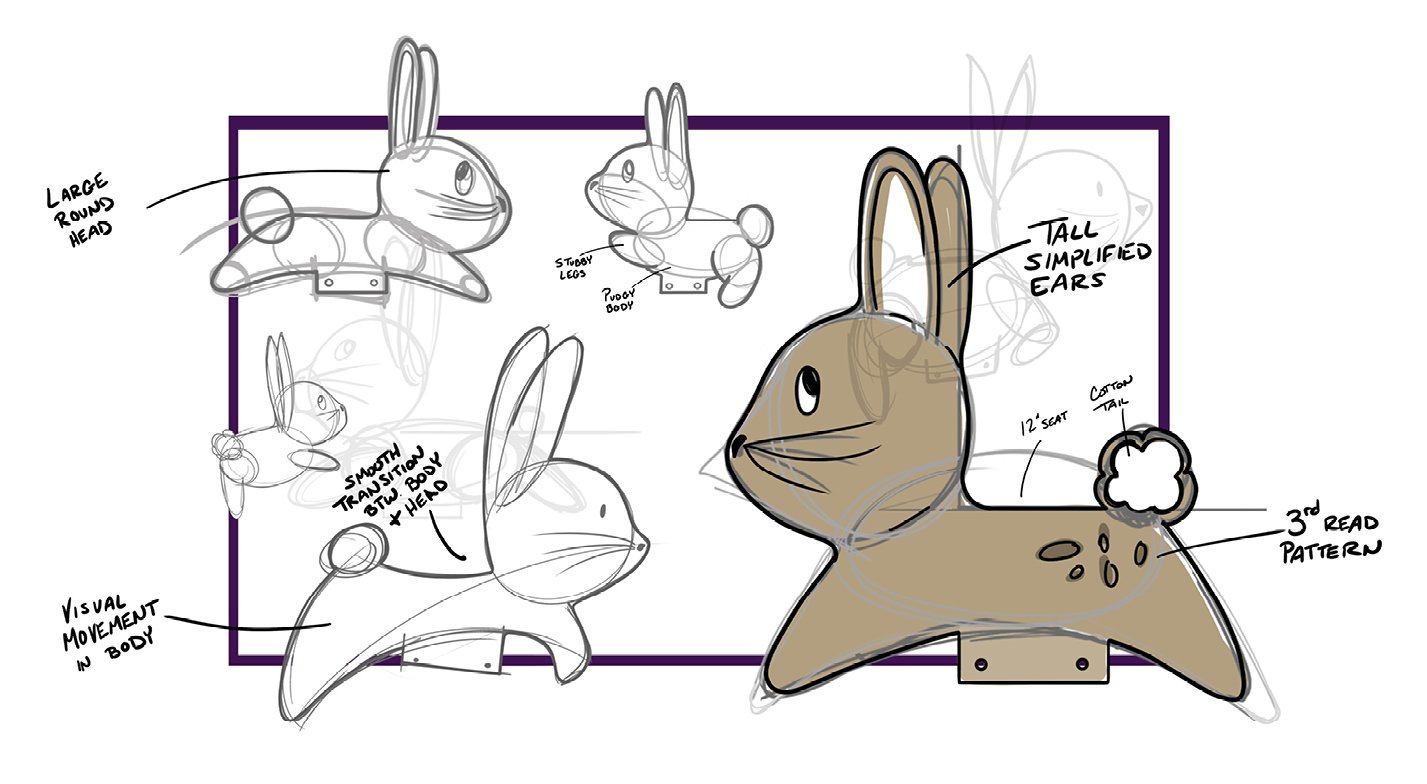

Iterative concept sketches were focused on finding the harmony between form and function. I didn’t want the shape of an animal’s body to be warped just to make room for the seat. The cool thing about these designs is the way they easily fit in with Burke’s existing design identity.

All of the new spring rockers were designed for highly-effective manufacturing techniques.

Choosing HDPE for the body, seat, and foot rests meant a faster manufacturing time. Dual-colored HDPE allowed us to get color contrasts that enhanced the design details without adding cost. And because HDPE is recyclable, any drops from the routing process could be turned into pellets and reformed into more sheet material for future designs.

Turtle

Duckling

Dolphin

Raccoon

Horse

Unicorn

Seahorse

The new designs received praise from both internal and external partners.

“I was recently awarded an RFP at a park here in the suburb of Atlanta. We had a great playground design, but I was told by the purchasing director that the entire committee loved the new spring rockers and that was what they kept talking about in the scoring meeting.

Keep up the good work and know that your awesome design and ideas are actually deciding factors in selling entire playgrounds!”

— Peter Jezerinac, Project Manager, PlaySouth Playground Creators